Background

A report from a Vermont climber about issues on the route War on Drugs at the 82 crag prompted inspection of the route’s fixed protection. While dealing with a separate set of problems, the last bolt identified as needing replacement was a 10mm Raumer double wedge bolt. These bolts were thought to be bomber in Northern Vermont schist along with their Fixe counterparts. What was troubling was the way in which the bolt was removed, or more accurately the ease with which it was removed. The manner and ease of removal indicated that the expansion mechanism of the bolt was in no way actually engaging or functioning. It is very troubling for a wedge bolt to be exhibiting behavior like this. Wedge bolts are often thought of as “fool” proof in that once they are installed in the hole, any attempt to remove them or load them will further engage the mechanical expansion effect keeping the bolt in the hole. The exception to this is in soft rock which typically does not allow for proper engagement of the expansion sleeves to achieve proper expansion.

Failure mode

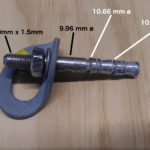

These bolts can be quickly identified with a torque wrench. Attempting to tighten the bolt and hit the target torque value will yield a nut that turns endlessly until the nut bottoms out on the threads of the stud. The corollary to this statement is that tightening the nut is backing the bolt out of the hole! Once the threads are bottomed out is it a simple matter to lightly funk the bolt out with a cable and hammer or sometimes even remove it by hand if the beginning of the hole is sloppy. Similarly one can remove the bolt simply by adding a spacer to allow the nut to be repositioned to allow for additional displacement of the bolt body. The below video shows the state after the threads have been bottomed out and how easily the bolt is removed.

Additionally, the below composite photo of four different Raumer single and double wedge bolts shows the state of the expansion sleeves once the bolt have been removed from the hole. As well, the high-resolution photo on the right taken at home also lends credence to this point. Note that the expansion sleeve shows little evidence of having ever expanded in all of the photos.

After conferring with Greg Barnes at the ASCA and discussing the video, photos, and taking measurements of the hole and bolt, the evidence suggests that the expansion sleeve is never “grabbing” the sides of the hole and allowing the rest of the bolt to pass-through ,engaging the tapered cone into the sleeve. The thought process here is that rock is too soft and/or the expansion sleeve is too burly and requires too much force/friction than is present to properly engage. Instead the minimal compression fit of the oversized expansion sleeve is the only resistance met. It is likely that with a regular spanner wrench, the friction of the compression fit is mistaken for proper engagement and tightening of the bolt. However, with a torque wrench it is readily apparent that the bolt is not properly tightening.

This theory is consistent with other observed performance shortcomings of this model of bolt in soft rock [1] as well as the input of a prominent fixed anchor manufacturer.

The seemingly random distribution of failures is likely attributable to the highly variable quality of green schist, wherein a vein of softer rock is often encountered which is likely promoting this behavior. This would be consistent with previously observed and understood failings of wedge bolts in soft rock. This is also likely the reason double wedge bolt models have had the best track record in schist as these bolts are designed for specific types of concrete where it is likely to have large pebbles in the concrete that may be shattered by drilling leaving a void. The theory behind this bolt’s design is that two expansion points provide an assurance that one of the expansion sleeves will engage in the matrix of the concrete. For schist, substitute a muscovite vein for a shattered pebble and we likely have a similar situation in many of our cliffs.

Impact

As of this analysis, an inspection has been performed on approximately 95 bolts on 13 different routes, installed by three different developers on three different cliffs. Of these 95 inspected bolts, 22 have shown to be non-functional.

The failure rate of this sample pool breaks down to 23%.

Given the consistency of the condition of the bolt and the manner in which it is removed as well as the spatial distribution of occurrences, it is hard to argue that this trend would not apply to all installations of these bolts in Northern Vermont schist.

The list of routes inspected and number of bolts removed are provided below.

| Route name | Failed bolts |

|---|---|

| Doggfather | 1 |

| War on Drugs | 1 |

| Politics of Dancing | 2 |

| Crimp Chimp | 4 |

| Year of the Dog | 3 |

| Quills | 1 |

| Arms Reduction | 4 |

| Truffle Hog | 1 |

| Pussy Galore | 1 |

| Wandering the Halls | 1 |

| Playground Bully | 1 |

| Anything for an A | 2 |

The Fixe bolts are likely unaffected by this particular problem as their expansion sleeve is significantly thinner and likely requires less “oomph” to engage. This is supported by tests of these bolts at 82 which showed all the protection bolts on Quills and Kid Charlemagne hitting specified torque easily. More confirmation is needed in order to dismiss this possibility however.

Proposed Action

Given the random distribution, likely the only way to identify these non-functional bolts is to “take off and nuke the entire site from orbit”, which is to say that each and every bolt should be torque tested to ensure proper function. Therefore it’ll be necessary to try and inventory all the routes that do or likely do have these bolts installed. Applying the roughly 25% failure rate to the total number of bolts will provide a ball park number of replacement bolts to ensure are available in order to effect the replacement of non-functional bolts as identified.